The SAP Digital Manufacturing Production Process Designer (PPD) enables digital factory specialists to visually model production processes and improve transparency on the store floor. With this low-code tool, you can design, deploy and activate production processes using BPMN 2.0 notation and monitor and log their execution. The Designer facilitates the centralized management of configurations and enables easy adaptation to changing production environments. This optimizes the interaction between machines and workflows, increases efficiency and reduces the need for programming skills.

We are happy to support you in the following areas:

| Machine Automation | With SAP Digital Manufacturing’s Production Process Designer, the Automation_Engineer or Production_Engineer roles can design an automation sequence to control machines without human intervention. This machine-to-machine or machine-to-system communication is coordinated by the Production Connector / SAP Plant Connectivity system and enables seamless integration and control of store floor services. By using master data and external service providers, complex automation processes, such as the assembly of a product by a robot, can be efficiently implemented and monitored, which significantly optimizes production processes. |

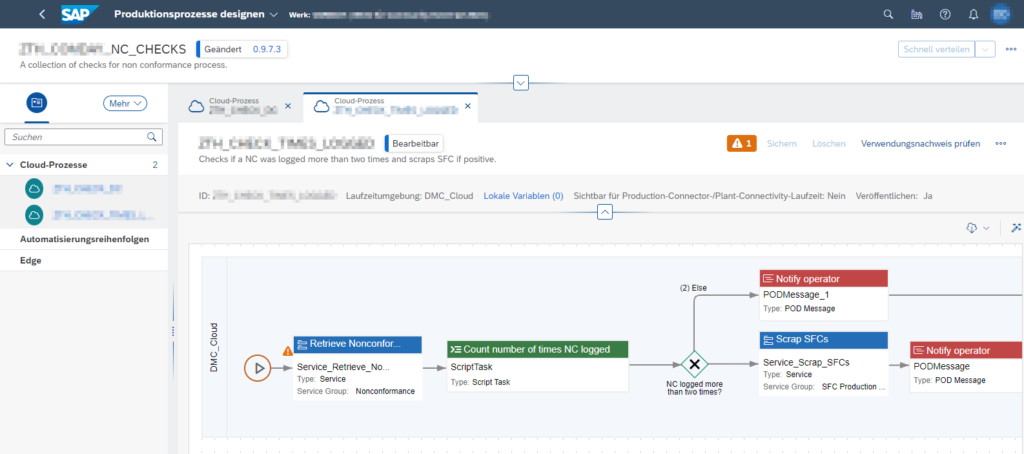

| Manufacturing Execution Automation | With SAP Digital Manufacturing’s Production Process Designer, digital factory specialists can design cloud-based processes to automate manufacturing execution. These processes enable the automation and enforcement of store floor activities, such as starting and completing a PSN (production control number) and data collection. By integrating and managing multiple web services, seamless control and monitoring of manufacturing processes is ensured, significantly increasing efficiency and accuracy in production. |

| Type conversation | With SAP Digital Manufacturing’s Production Process Designer, digital factory specialists can efficiently manage type conversion to ensure data consistency when defining input and output parameters. By supporting different data types such as string, boolean and array and their convertibility, flexibility and accuracy in process modeling is increased. This enables seamless integration and processing of data, optimizing the efficiency and reliability of manufacturing processes. |

| Debug Production Processes | With SAP Digital Manufacturing’s Production Process Designer, specialists with the Production_Engineer role can debug cloud-based production processes after deployment. This debugging function enables the step-by-step checking of process execution in order to efficiently identify and rectify problems. The process designer helps to set breakpoints and check input and output parameters without affecting the normal execution of production processes. |

| SAP Business Accelerator Hub | The SAP Business Accelerator Hub offers Digital Factory specialists and developers a wide range of sandbox APIs for various SAP products such as SAP S/4HANA, SAP BTP and SAP Digital Manufacturing. These APIs make it possible to create extensions, applications or integrations and validate them with test data. For SAP Digital Manufacturing in particular, the automatically created runtime web server in the “Manage Web Server” app contains cloud services that can be used with a default destination created in SAP BTP Cockpit, making it much easier to develop and integrate production processes. |