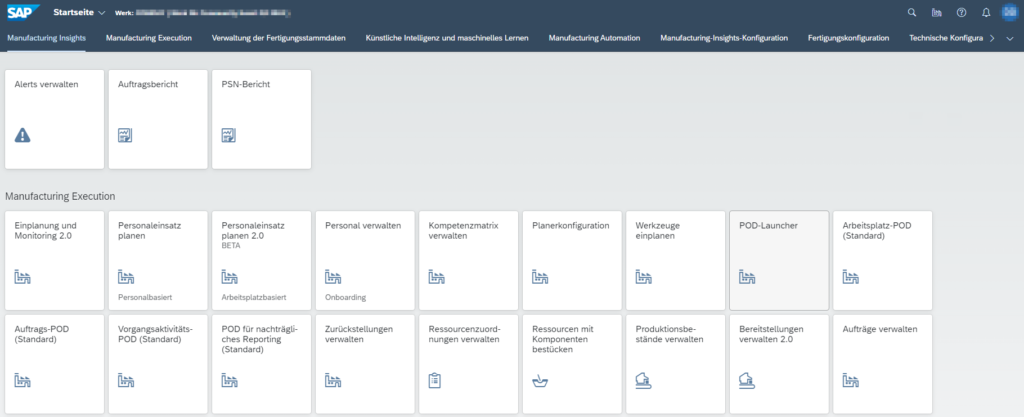

The SAP Digital Manufacturing Production Operation Dashboard Designer enables digital factory specialists to efficiently manage and customize production operations through user-friendly, modular dashboards. With the Production Operator Dashboard (POD), operators on the store floor can collect data in real time and manage SFCs (Shop Floor Controls), resulting in increased transparency and productivity. The flexible configuration and the ability to create custom plug-ins enable tailored solutions to meet the specific requirements of different production environments.

We are happy to support you in the following areas:

| POD Designer | SAP’s POD Designer enables Digital Factory specialists to easily and quickly create customized Production Operator Dashboards (PODs) with drag-and-drop functionality and real-time previews. With POD Designer, you can configure customized layouts and specific plugins to meet the unique requirements of your production environment. This flexibility and customizability improves efficiency and transparency on the store floor by providing tailored solutions for different industries. |

| Launching POD | With the SAP POD Launcher app, Digital Factory specialists can efficiently launch and manage Production Operator Dashboards (PODs) in separate windows. This app makes it possible to create and immediately use custom PODs or applications with special plugins, which significantly improves flexibility and adaptability in the production environment. By easily assigning and managing the required PODs directly in the POD Launcher, efficiency is increased and seamless integration into the production process is ensured. |

| Work Center POD | The SAP Digital Manufacturing work center POD supports digital factory specialists in the efficient execution of production orders and the paperless management of production data. This app enables the organization of production control numbers and operation activities in a work center where complex assembly processes and critical data collection are performed. The workstation POD gives users access to key manufacturing data, plug-ins and work instructions, significantly improving visibility and efficiency on the store floor. |

| Order POD | SAP Digital Manufacturing’s Order POD enables digital factory specialists to efficiently execute and manage process and manufacturing orders transferred from integrated ERP systems. With this app, users can view order header information and phase/process details, report good and scrap quantities, and manage key production activities directly on the store floor. This functionality improves the transparency and efficiency of manufacturing processes by enabling seamless integration and management of orders in real time. |

| Operation Activity POD | SAP Digital Manufacturing’s Operation Activity POD supports Digital Factory specialists in the efficient execution of production orders and the management of PSNs (production control numbers) in specific operation activities. This app makes it possible to select PSNs, view their status and relevant components, and manage necessary work instructions and deviations. The standard operation activity POD can be customized to specific requirements to optimize production processes in high-tech assembly, vehicle production and electronic and medical device manufacturing. |

| Post-Production Reporting POD | The DM POD for retrospective reporting from SAP Digital Manufacturing enables digital factory specialists to efficiently capture and post production data after the execution of production orders on the store floor. This app supports easy entry of order execution data reported on paper and ensures that all postings are reported back to the appropriate backend system. Through seamless integration with SAP S/4HANA Cloud and SAP ERP, the POD optimizes the traceability and accuracy of production data, significantly improving efficiency and transparency on the shop floor. |

| Standalone Nonconformance POD | SAP Digital Manufacturing’s POD for Stand-Alone Deviation allows Digital Factory specialists to view and log deviations for production control numbers (PSNs), regardless of their status or location. This POD is ideal for quality engineers and repair technicians who need to capture deviations outside of the regular manufacturing process, even if the PSN is not on the store floor. By using specialized plugins such as Deviation Data Tree and Deviation Selection, this POD provides a flexible and comprehensive solution for quality monitoring and assurance on the shop floor. |

| Custom POD | Develop customized production applications that meet specific requirements not covered by standard POD types with custom plugins for PODs in SAP Digital Manufacturing and the Business Technology Platform (BTP). These plugins allow customization of the user interface and functions by controlling specific parameters in the URL to ensure optimal integration and functionality. By using tools such as the Yeoman generator, the development and implementation of these custom plugins can be significantly accelerated and simplified, increasing efficiency and flexibility in the production environment. |