The SAP Manufacturing Execution System (MES) enables digital factory specialists to digitally control, monitor and automate manufacturing processes, enabling cost-effective production with a batch size of one.By digitizing manufacturing processes and integrating business software, SAP MES offers a cost-efficient and resource-saving methodology based on Industry 4.0 technology.With near real-time information through IoT solutions, companies gain detailed insights and increased transparency into their operations, improving product reliability and traceability. Flexible process modeling and simplified integration with SAP ERP support both cloud and on-premise deployments, creating a comprehensive and customizable solution for production control.

We are happy to support you in the following areas:

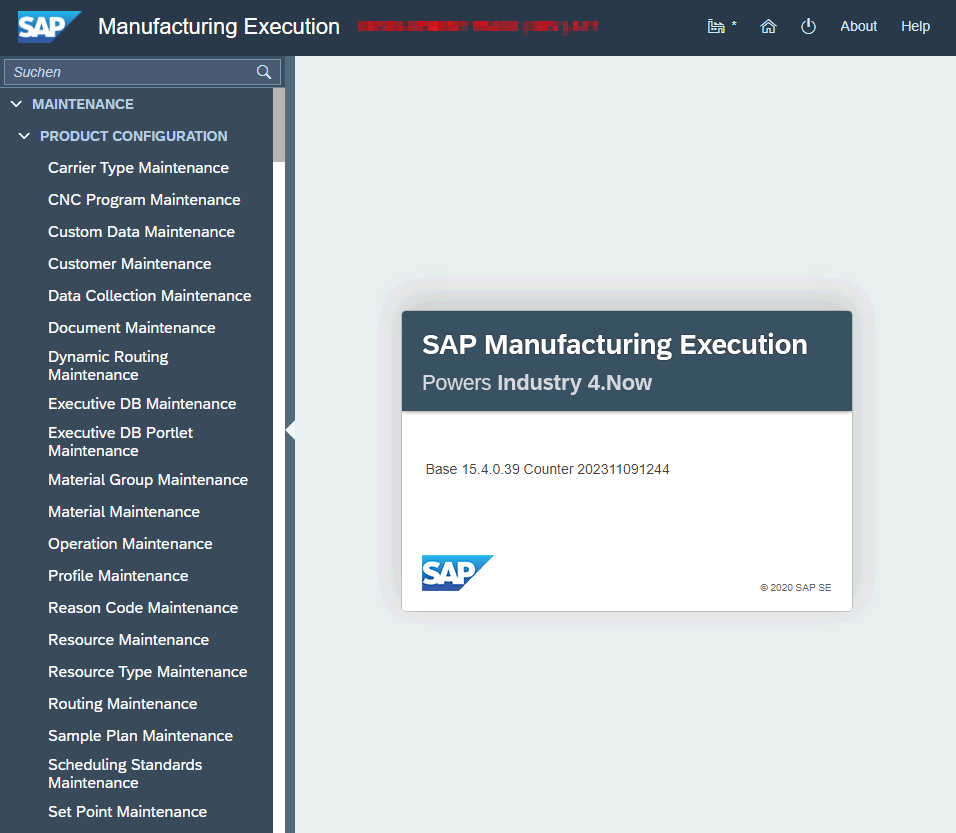

| Manufacturing Execution System (MES) | A Manufacturing Execution System (MES) such as SAP Manufacturing Execution (SAP ME) enables manufacturing and store floor operations to be centrally controlled, automated data collection to be performed and defects to be efficiently tracked and rectified. SAP ME integrates business systems with store floor activities and provides comprehensive visibility at component and material level, both for individual and global installations.By collecting and integrating data from multiple sources, SAP ME ensures that products are designed and built correctly from the start, improving production quality and ensuring regulatory compliance. |

| Functions | With SAP ME, you can manage production data, control production processes via the Production Operator Dashboard (POD) and ensure real-time visibility across the entire production cycle. The integration of genealogy enables complete traceability, while the non-conformance functionality helps to identify and eliminate quality defects, significantly improving the overall quality and efficiency of production. |

| Configuration | The configuration of a Manufacturing Execution System (MES) from SAP offers digital factory specialists the opportunity to precisely control and optimize manufacturing processes. Comprehensive instructions for activities such as barcode scanning, data archiving, complex assembly and OEE measurement simplify the implementation and customization of the MES. Detailed how-to guides help to make integration, data processing and analysis efficient, significantly increasing production performance and transparency. |

| Migration | The migration from SAP Manufacturing Execution (SAP ME) to SAP Digital Manufacturing (SAP DM) offers numerous benefits through integration into a cloud-based environment. SAP DM, the native successor to SAP ME, enables improved functionality and flexibility, particularly through the use of work-in-progress transports and resource orchestration. The migration enables companies to digitally control, monitor and automate their manufacturing processes, resulting in more efficient and cost-effective production. The migration to SAP DM ensures long-term support and further development of the production systems, as basic support for SAP ME will be discontinued by 2030. Using the migration canvas helps to systematically plan and successfully implement the migration. |

| Archiving | SAP ME Archiving enables the archiving of production data (ShopOrder and SFC, as well as the dependent data objects) by transferring completed or no longer required data from the WIP database to the ODS database. This feature helps to optimize system performance and ensure compliance with retention requirements. By integrating SAP ME with the SAP HANA database, improved data processing and storage is achieved, resulting in faster data retrieval and better reporting. |